Precision mechanical turning

Production

Specialised in machining and manufacturing of mechanical components

Ameta Srl designs and manufactures, internally or according to the customer’s technical drawings, components and small parts from bars in different materials and metal alloys.

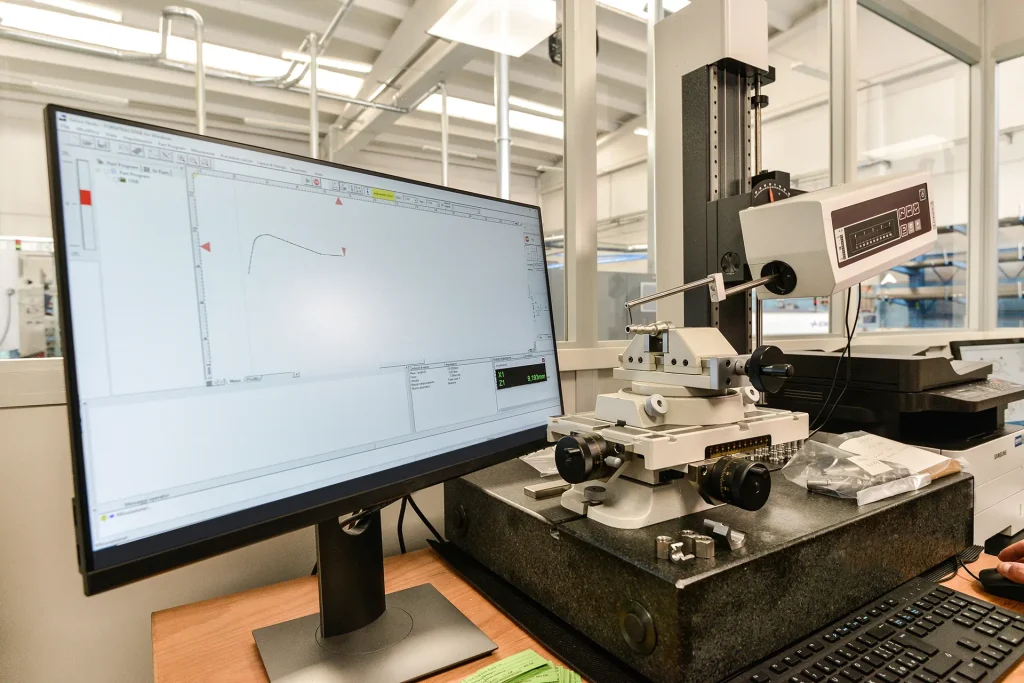

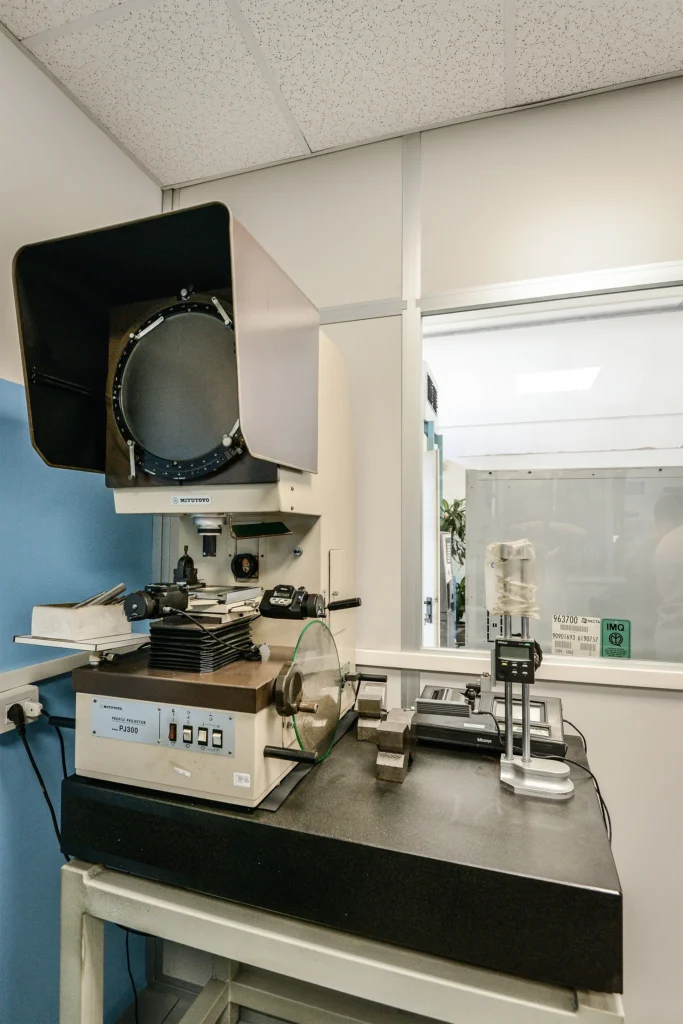

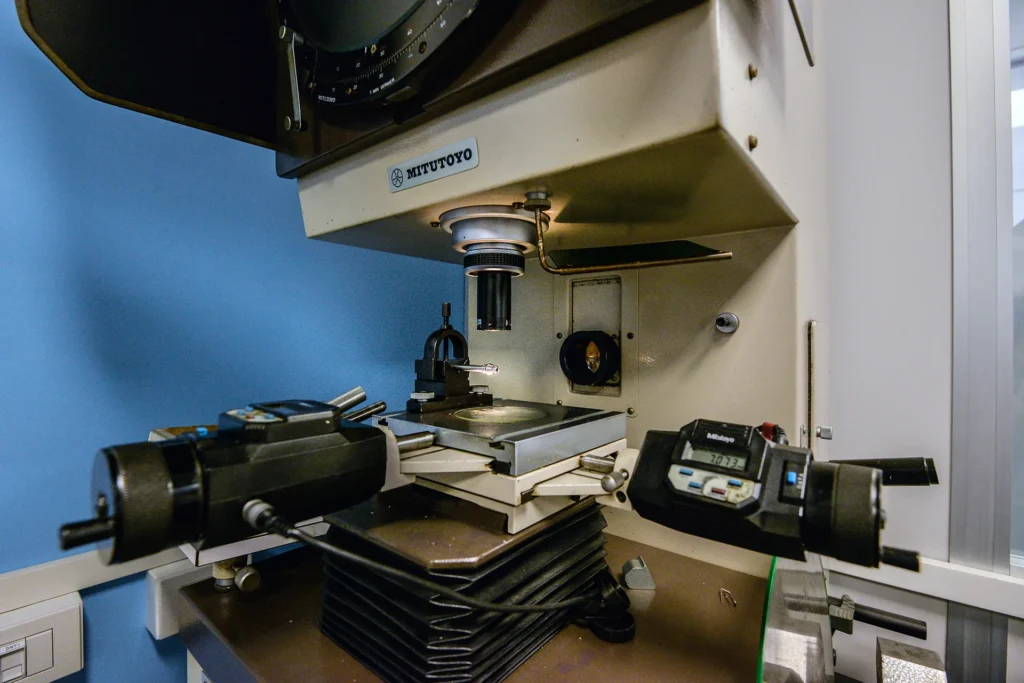

The modern, digital and advanced machinery used in production allows us to obtain:

Thanks to our state-of-the-art equipment and machinery, we meet the needs of every manufacturer, industrial or artisan, who needs mechanical components and precision small parts.

We produce high quality parts of projects that follow a model requested by the customer or designed within the company.

Before being put into production, the product is studied in such a way that it respects all the quality parameters.

Production technology: CNC Fixed Head & Fantina Mobile Ø from 3mm to 42mm

Design according to components and construction materials